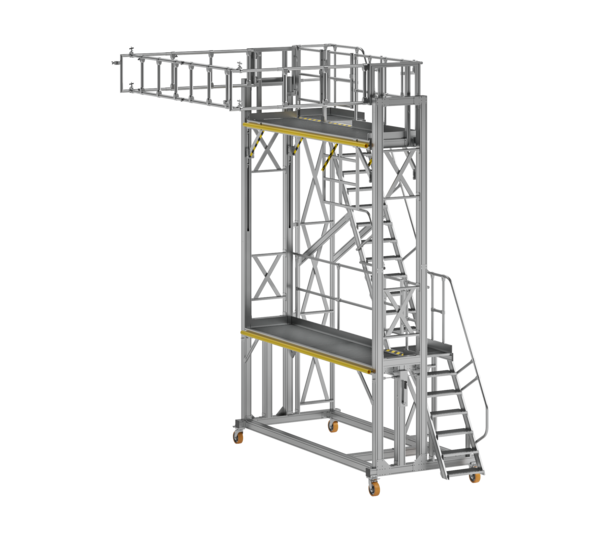

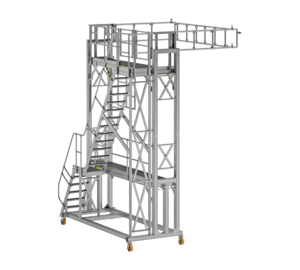

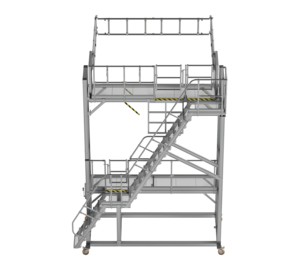

Mobile work platform with safety cage

Specifications

Information

- Platform 1 (rigid): Platform length (PFL): 3,660 mm

- Platform 1 (rigid): Platform width (PFB): 850 mm

- Platform 1 (rigid): Platform height (PFH): 1,800 mm

- Platform 1 (rigid): Decking: Steel grating R13

- Platform 2 (height-adjustable): Platform length (PFL): 3,660 mm

- Platform 2 (height-adjustable): Platform width (PFB): 850 mm

- Platform 2 (height-adjustable): Platform height max. (PFHmax): 5,000 mm

- Platform 2 (height-adjustable): Platform height min. (PFHmin): 3,900 mm

- Platform 2 (height-adjustable): Adjustment range (V): 1,100 mm

- Platform 2 (height-adjustable): Decking: Steel grating R13

- Safety cage: Length (SKL): 3,660 mm

- Safety cage: Width (SKB): approx. 2,000 mm

- Safety cage: Height (LH): approx. 600 mm

- Safety cage: Long side designed to be pluggable; can be clamped with 2 telescopic support legs

- Working platforms can be used individually or together

- Stairs: Platform length 1 (PFL1): 830 mm

- Stairs: Platform length 2 (PFL2): 630 mm

- Stairs: Platform width (PFB): 650 mm

- Stairs: Platform height top (PFH1): 1,800 mm

- Stairs: Platform height top (PFH2): 5,000 mm

- Stairs: Step width (SB): 600 mm

- Stairs: Step depth (ST): 240 mm

- Stairs: Projection (A): approx. 4,200 mm

- Stairs: Inclination (W): 60 °

- Stairs: Covering: Steel grating R12

- Surface load: 1.50 kN/m²

- Total load: 500 kg

Client's Request and Task

Our client, a public transport operator, faced the challenge of optimizing maintenance and repair work on different types of trams. The focus of the customer's needs was on ergonomic and safe work design for the maintenance staff and compliance with all relevant legal regulations and standards. Additionally, high mobility within the workshops was required, with the work platform needing to be adaptable to various tram models.

- Ergonomic and safe work environment for employees on a mobile work platform

- Stable, reliable, and standard-compliant execution

- Flexible use with different types of trams

- Use of corrosion-resistant aluminum alloys

- Compliance with all relevant regulations, guidelines, standards, laws, and recommendations

Our Solution

Modular Work Platform with Safety Basket

To meet the client's requirements, we developed a mobile work platform with an integrated safety basket. The construction consists of two support frames that carry a lower rigid and an upper height-adjustable platform. The platforms are designed for high load capacity and offer ample space for tools and materials.

Flexible Adjustment and Ergonomics

The upper platform can be continuously adjusted using a threaded spindle and hand crank to accommodate the varying heights of the trams. The stable, two-flight staircase with a handrail allows for safe ascent. A foldable side safety basket provides additional fall protection and allows two platforms to be connected to extend the work area.

Safety and Mobility

The mobile frame is equipped with four robust casters, each with locking brakes, ensuring safe positioning of the platform. Self-closing safety doors and rigid railings enhance work safety. Rubber strips on the side facing the product serve as impact protection and prevent damage to the trams.

Technical Specifications

The platforms are made of non-slip steel grating and are designed to accommodate a surface load of 1.50 kN/m² and a total load of 500 kg. The height-adjustable platform offers an adjustment range of 1100 mm, allowing for ergonomic working at various heights.

Conclusion

The mobile work platform with a safety basket meets all the requirements set by the customer for flexibility, safety, and ergonomics. It is specifically designed for the maintenance and repair of trams and supports efficient and standard-compliant work. The use of high-quality materials and thoughtful construction ensures the product's long life and reliability.

- Corporate certification: ISO 9001

- Corporate certification: ISO 14001

- Corporate certification: EN 1090

- Corporate certification: EcoVadis

- RoHS

- REACH

- The MUNK Group complies with a Code of Conduct

- The Supply Chain Act does not apply due to our size

- The materials used are listed in the technical specification

- Resource-saving production: own photovoltaic systems

- Energy-efficient consumption during production: LED lighting

- Repairability, durability and quality: 15-year warranty on series products made in Germany

- Recyclability: Our products are mostly made of aluminium, steel or wood and can be fed directly into the recycling process.

- Socially acceptable working conditions in production: fair wages, gender equality

- Economical and recyclable packaging: no use of polystyrene, predominantly use of wood and cardboard, small amounts of plastic

- No health hazards for the users

Custom access equipment: 5 stars for your safety

Trust in us as your competent partner in the field of individual access equipment solutions. We are industry leaders from analysis to conception and design to first-class after-sales service.

★ Analysis

We set standards in the evaluation of access equipment requirements. Our experts take sufficient time to understand your specific needs. After a thorough analysis, we will present you with a tailor-made design that is perfectly tailored to your individual circumstances. Rely on us to identify your challenges and solve them in an innovative way.

★ Concept

We are leaders in the planning of special designs. With creativity, technical know-how and a deep understanding of access equipment, we develop pioneering concepts. Our experienced team designs outstanding solutions that meet the highest safety standards and maximise your efficiency and ergonomics. Let yourself be impressed by our competence and innovative strength.

★ Design

We set the bar high in design. Our engineers and production planners have unique specialist knowledge and many years of experience in the field of access equipment. With the latest technologies and high-quality materials we realise your concept down to the smallest detail. Precision and quality are the first priority – for your special designs that meet the highest demands.

★ Production

In our modern production halls at our headquarters in Günzburg, we can implement your planning and wishes professionally and efficiently. Our specialists in access equipment, electronics and mechanics always have only one thing in mind: Quality that delivers what it promises. That's why every design, whether large or small, is manufactured with the highest quality and precision and thoroughly tested before shipment.

★ After sales

Our commitment does not end with the completion of the special design. We are unbeatable in after-sales service. With assembly, maintenance, testing and repairs, we ensure that your special design always remains in perfect condition. Our reliable team provides you with superior customer service and ensures that your satisfaction is first and foremost.

Special constructions

From decades of experience, we know that individual requirements require special solutions. That's why we are here to help you realize your custom construction.

Get inspired by our reference products and make your unique idea a success. We look forward to supporting your project with our expertise and dedication. Contact our competent team for more information and assistance.

With MUNK Group by your side, your custom construction becomes a reality: Safety. Made in Germany.

What we offer

- On-site consultation and project planning

- Custom development according to your requirements

- Precision manufacturing

- Functional and cost-effective access solutions

- Maximum workplace safety

- Fast delivery

- Compliance with all relevant German, English, and international standards and regulations, such as BetrSichV, DGUV regulations, Machinery Directive 2006/42/EC