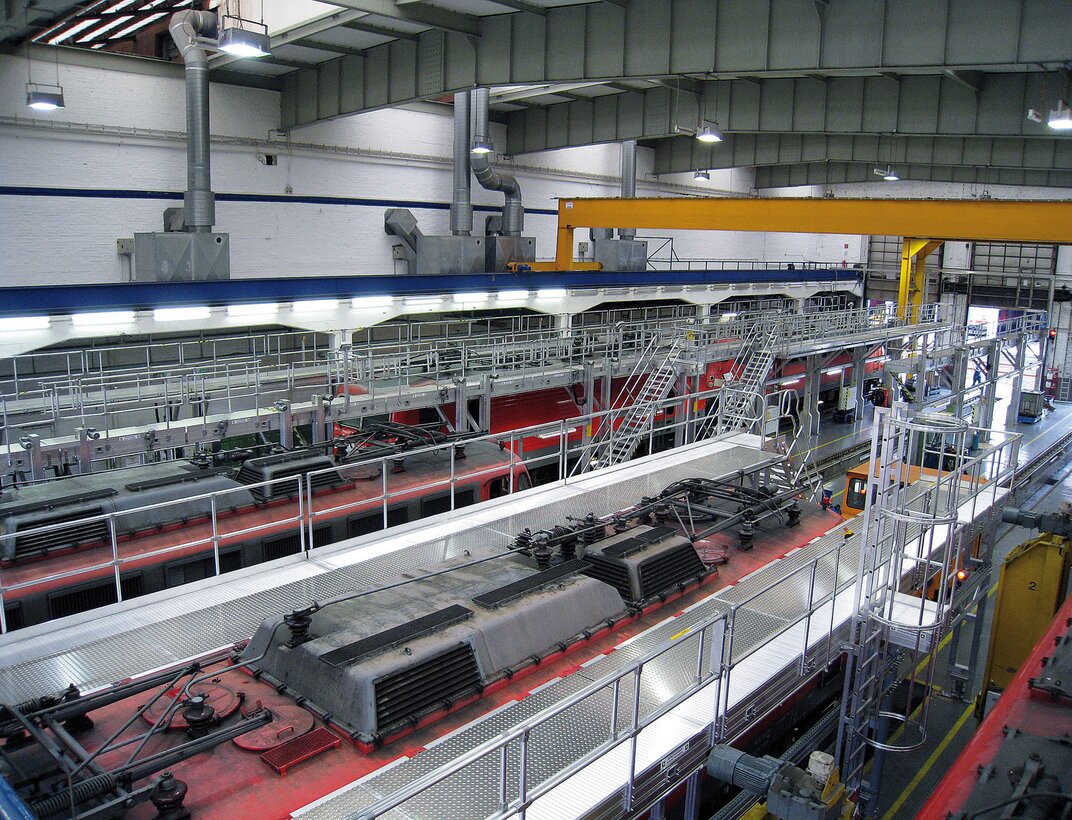

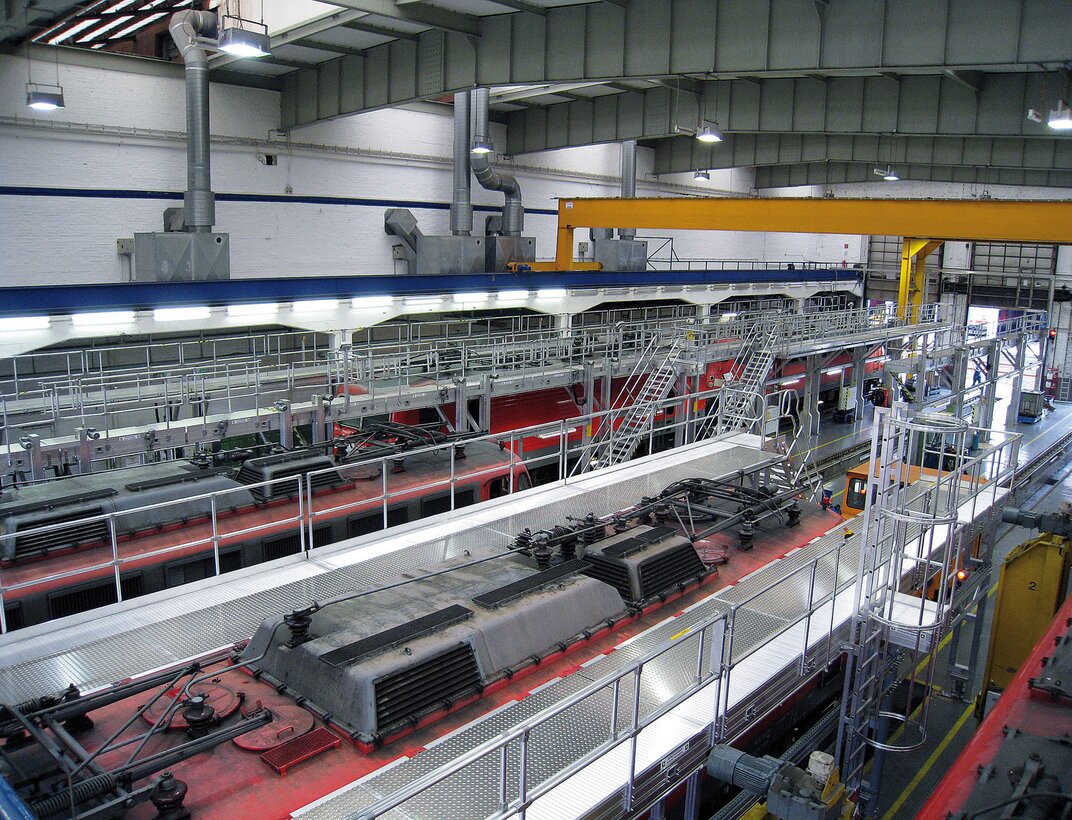

The three DB Regio roof work stands consist of a total of six catwalk systems, which are permanently installed in pairs on both sides of the three maintenance tracks. The roof work stands are 50, 20 and 15 metres long respectively. On both sides of the maintenance tracks, the platforms of the walkways are each 1000 mm wide; in addition, the platforms can each be extended horizontally by 500 mm at the push of a button. In this way, the total working area of 170 m2 can be extended by 50 percent to 255 m2.

The platform height is 3.0 metres; with the help of a screw jack with electric motor, it can be extended to a height of 4.0 metres within one minute. "This gives us tremendous flexibility for the future; we are already equipped for new vehicles of future series," says Bert Kiworra.

Working with zero clearance was also important to the vehicle technology team leader. Here, the work platforms can drive directly up to the outer skin of the vehicles and dock there. This not only increases work safety, but also efficiency, because if there is no longer an intermediate gap, no more tools can fall down. And the employees no longer have to work in a hyperextended posture.

For the first time ever, the employees of the maintenance team in Braunschweig can go to work in the ergonomic working position throughout, as really every height point can be approached with the electrically adjustable systems. Each side of the system can be moved by a single employee, either from the ground or standing on the work platform, with the help of a control device. This means there is no more uncomfortable bending or kneeling, as was often necessary in the past with the rigid design.

"For us, optimal work safety is the trump card. And we have also placed the highest value on this with the roof work stands for DB Regio in Braunschweig," says Ferdinand Munk, Managing Director of Munk Günzburger Steigtechnik. All catwalks are secured with railings at the back and sides. In addition, Munk Günzburger Steigtechnik has equipped the working platforms on the train side with pockets so that railings can also be inserted there. "This is always important when the train length is shorter than the length of the catwalk," says Munk.

Climbing up and down onto the working platforms is also comfortable and safe, because so-called vario stairs with self-closing safety doors are fitted to the sides of the catwalks. The steps of the stairs always remain in a horizontal position within the automatic height adjustment and thus ensure safe walking at all times. As a further safety feature, the catwalks from Munk Günzburger Steigtechnik have access ladders for rapid descent in the event of an emergency.

Bert Kiworra, meanwhile, is pleased with the combination of freedom and safety he has gained: "We still have a 20-tonne crane in our hall for lifting out the engines. Now we can finally use it effectively. Until now, when we wanted to remove the roof of locomotives on platform 7, our employees had to climb onto the roof with the help of ladders to attach the cable chains. Fortunately, those days are now finally over."

The changeover to the new maintenance era was as simple as can be for DB Regio in Braunschweig. The roof work stands from Munk Günzburger Steigtechnik were installed within a week without having to interrupt the maintenance work on the locomotives and railcars.

The Munk Günzburger Steigtechnik access equipment was manufactured at the company's headquarters in Günzburg and has the certified "Made in Germany" certificate of origin.